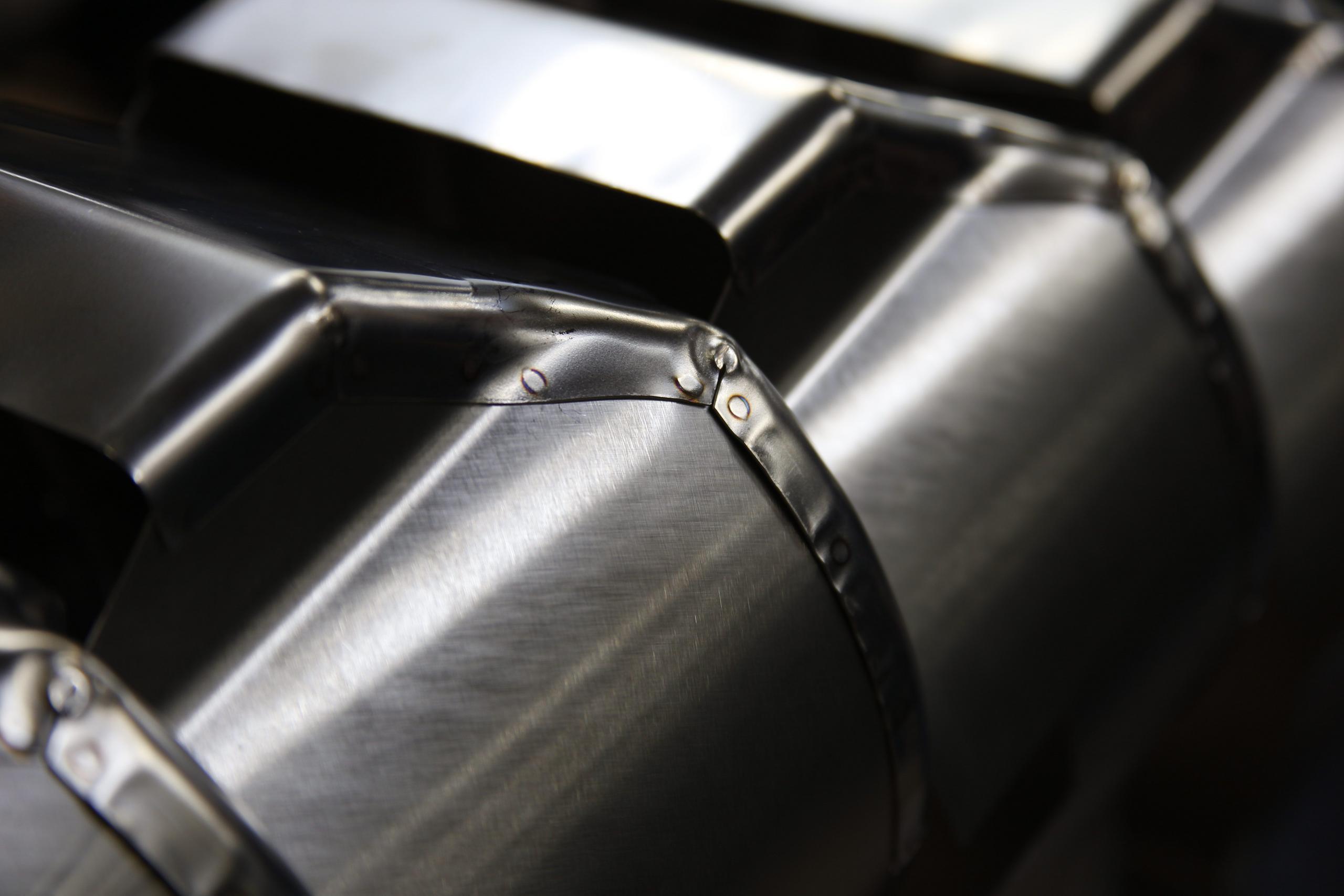

Sheet Metal Fabrication

New equipment and automation in our St Paul facility keeps us in the lead of USA metal fabrication suppliers. This capability is often the backbone of mechanical assemblies that utilize components from other Quality Tool production factories.

Medical Equipment Core

Quality Tool proactively offered a DFM concept to our customer which reduced cost by 50% and lead time by 3 weeks.

Rack Mount Chassis

Quality Tool’s QTI Design Division developed this product for low cost production and speed to market. Prototypes and production were processed at Quality Tool and special modifications are easily produced.

Card Guide:

We manufacture many card guide trays.

Standard or custom tooling is available for these applications.

Most guide trays are produced as assemblies including clinch hardware, EMI gasketing, and labelling.

Ready to Start Your Project?

..or project your start? Our project managers can help you develop a plan that will enable you to meet your launch timing, at your target price.

Additional Capabilities

View AllSorry, there are no results.