Stampings

Our 10,000 sq. ft. custom tooling department sets us apart from our competitors for cost-effective and fast start up of tight tolerance or mid/high volume metal stamped parts.

Our stamping capability can be a key element to optimizing your part’s metal fabrication process for best cost.

Vast Capacity

With presses ranging from 25 tons to 300 tons, Quality Tool produces thousands of discrete parts on a daily basis.

In House Tooling

10,000 sq ft tooling factory dedicated to our stamping customers. Tooling for life. Maintained and replaced as needed.

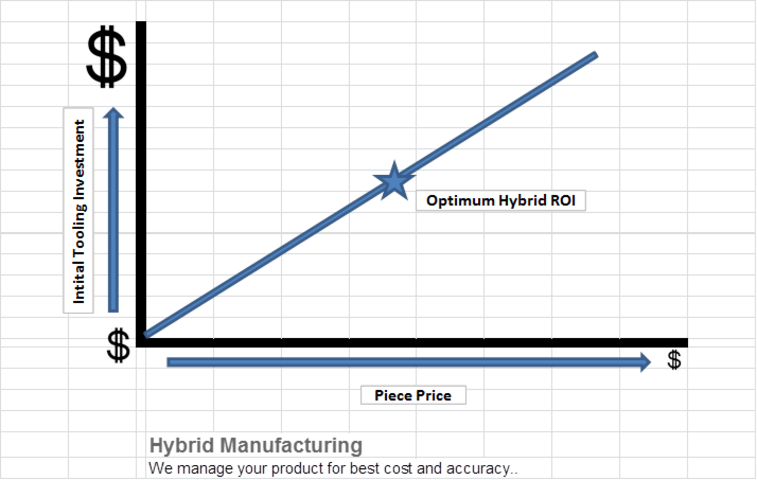

Hybrid Manufacturing

We manage your process for best cost, accuracy and ROI. Many blended options of mixed tooling levels can be quoted for your evaluation.

Ready to Start Your Project?

...or continue, or finish, your project? Custom Stamping is an important consideration for lowest product cost; and repeatable, accurate, and fast production.

Additional Capabilities

View AllSorry, there are no results.